In the ever-evolving landscape of material science and engineering, the demand for precision and efficiency in processing techniques has never been higher. At Hartek Technologies Co., Ltd, we are proud to introduce our state-of-the-art Lab Extruder, a cutting-edge solution designed to meet the rigorous demands of research and development in various industries. This article explores the features, benefits, and applications of our Lab Extruder, highlighting its role in advancing material processing technology.

Key Features of Hartek’s Lab Extruder

- Compact Design: Our Lab Extruder is engineered with a compact footprint, making it ideal for laboratories with limited space. Despite its size, it does not compromise on performance, offering high throughput and efficiency.

- Versatile Processing Capabilities: The Lab Extruder is capable of processing a wide range of materials, including thermoplastics, thermosets, and composites. This versatility allows researchers to experiment with different formulations and processing conditions.

- Precision Temperature Control: Equipped with advanced temperature control systems, our extruder ensures uniform heating throughout the processing chamber. This feature is crucial for achieving consistent material properties and optimizing the extrusion process.

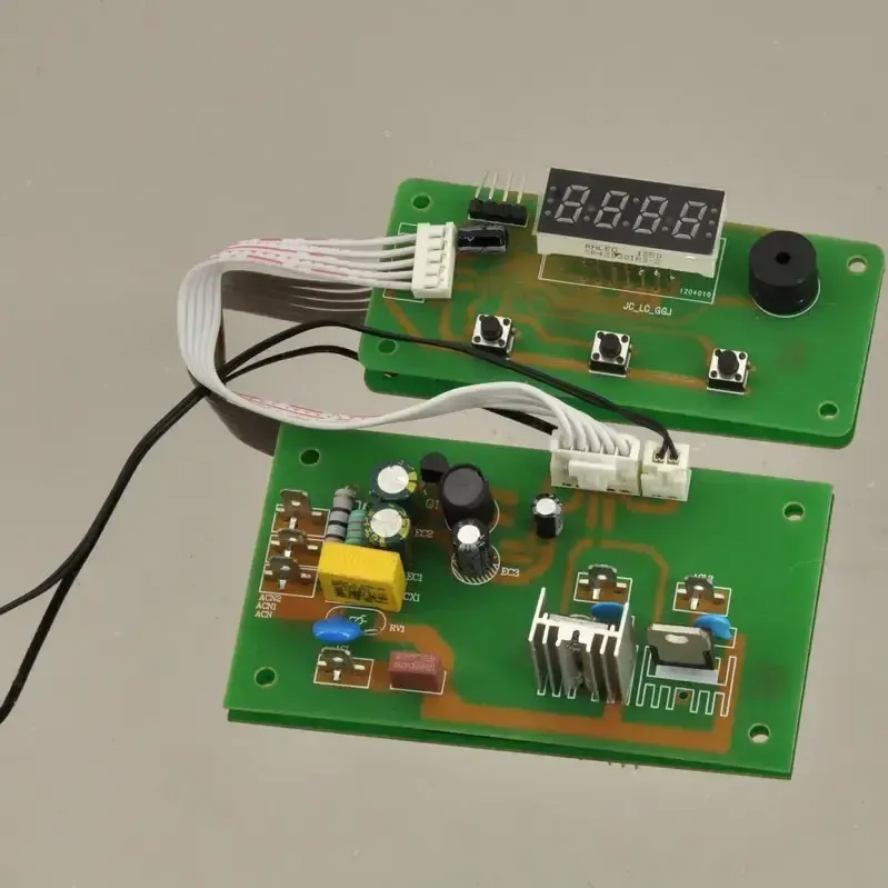

- User -Friendly Interface: The Lab Extruder comes with an intuitive control panel that allows users to easily set parameters, monitor performance, and make real-time adjustments. This user-centric design enhances the overall user experience and facilitates efficient operation.

- Scalability: One of the standout features of our Lab Extruder is its scalability. Researchers can use the same equipment for small-scale experiments and later transition to larger production runs without the need for significant modifications.

Benefits of Using Hartek’s Lab Extruder

- Enhanced Research and Development: The Lab Extruder accelerates the R&D process by enabling rapid prototyping and testing of new materials. This capability is essential for companies looking to innovate and stay ahead in competitive markets.

- Cost-Effective Solutions: By allowing for small batch processing, our extruder minimizes material waste and reduces costs associated with large-scale production. This is particularly beneficial for startups and research institutions with limited budgets.

- Improved Material Properties: The precise control over processing conditions helps in achieving superior material properties, such as enhanced strength, flexibility, and thermal stability. This is vital for applications in industries like automotive, aerospace, and consumer goods.

- Streamlined Workflow: The Lab Extruder integrates seamlessly into existing laboratory workflows, allowing for efficient collaboration among researchers and engineers. Its compact design and ease of use contribute to a more organized and productive work environment.

Applications of Lab Extrusion

The applications of Hartek’s Lab Extruder are vast and varied. It is widely used in:

- Polymer Research: For developing new polymer blends and composites with tailored properties.

- Food Processing: In the formulation of extruded snacks and other food products, ensuring optimal texture and flavor.

- Pharmaceuticals: For the development of drug delivery systems and other pharmaceutical formulations.

- Additive Manufacturing: As a precursor to 3D printing processes, enabling the creation of complex geometries with advanced materials.

At Hartek Technologies Co., Ltd, we are committed to pushing the boundaries of material processing technology. Our Lab Extruder stands as a testament to our dedication to innovation, quality, and customer satisfaction. By providing researchers and manufacturers with the tools they need to succeed, we are helping to shape the future of material science. Whether you are in academia or industry, our Lab Extruder is the perfect partner for your next project. Explore the possibilities with Hartek Technologies today!